DIY: Removing / Replacing Riveted Clutch Basket

/A quick how-to on removing and replacing your worn clutch basket. Baskets will usually get grooves worn into them over time from the plate tabs and eventually restrict movement, causing the clutch to drag. The Husqvarna was doing just that so a replacement basket was purchased.

Many baskets are riveted to the steel ring gear behind them. Here's how to remove the basket without damaging the gear.

Use a center punch to mark the center of each rivet then drill through with a small bit (1-2mm). Use some cutting paste to save your bits from all the drilling you're about to do. I use "Coolcut" from Walter.

This clutch has a sleeve bearing. Make sure not to touch the inner bearing surface. It'll likely have metal shavings on it and you don't want to scratch it. I put my gear under running water and then blew it out with compressed air after separating the 2. If yours has a ballbearing tape it off before drilling.

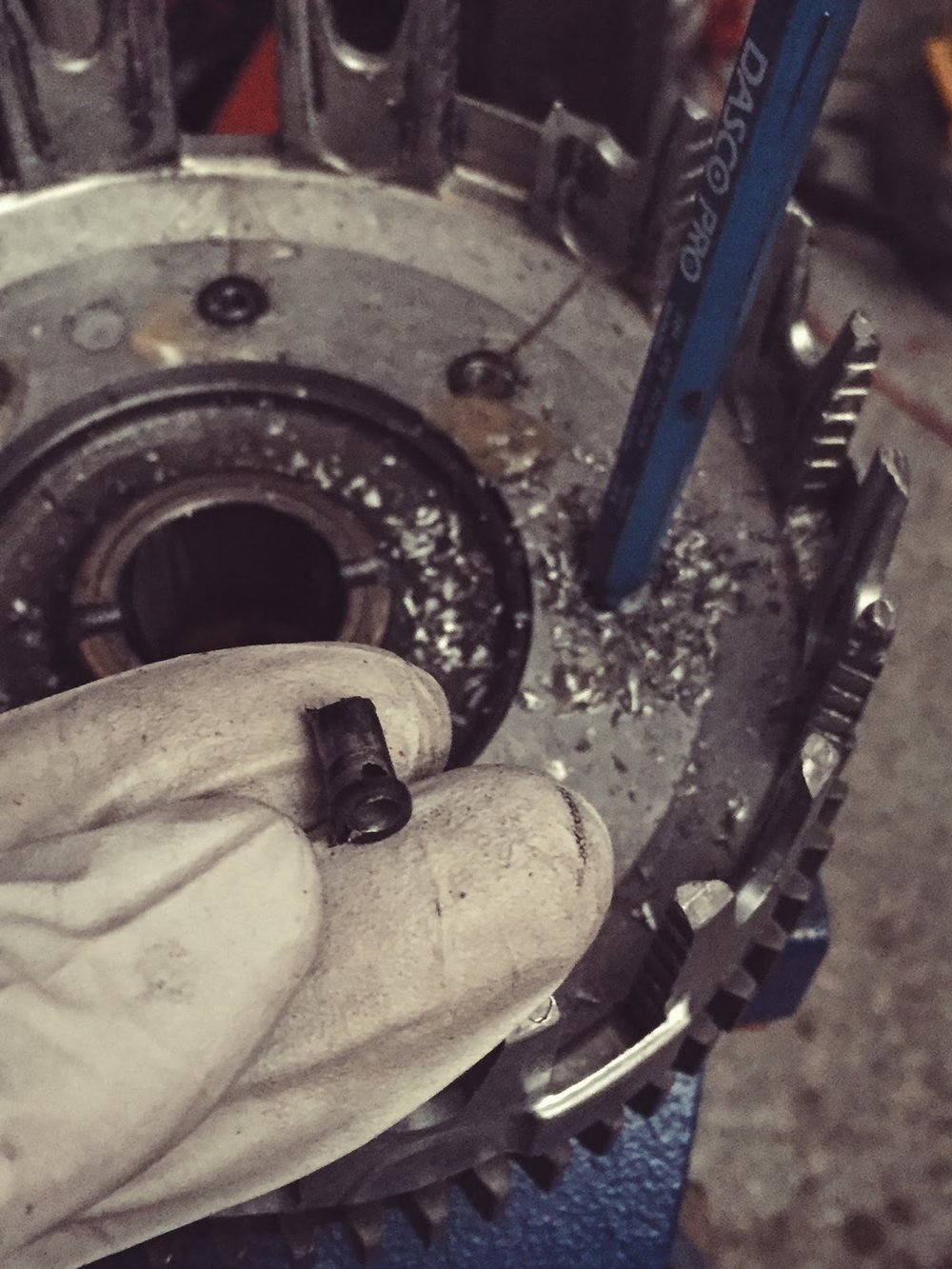

Step up to a 4-5mm bit and drill a slightly larger hole. Make sure your bit is narrower than the holes in the gear so you don't bore out the steel. (check out the grooves in the basket and the broken prong.)

Here's what it'll look like from the backside. What you've done is weakened the structural integrity of the rivets and given yourself a guide hole for the next step.

Now choose a bit that has the same diameter as the rivet head.

Drill down until you start hitting the aluminum of the basket. You can feel the different between the steel rivet and aluminum basket. What you need to do is drill away the rivet's head. Eating into the basket a bit is fine since it's trash.

Next find a punch that's larger than your pilot hole but smaller than the hole in the steel gear. Punch out the remaining rivet. It should pop right out with a few whacks. If not then you probably haven't drilled away the rivet head entirely.

Here's what's left of the rivet. Repeat, repeat, repeat.

Off it goes. Remember, wash the shavings off with running water and compressed air before applying assembly grease to the bearing surface.

Many aftermarket clutch baskets are reattached with bolts instead of rivets. I scored this lightweight Surflex billet clutch basket off eBay. (One of the few company's that makes one for the TE) It came with steel rivets instead of bolts. To reapply the rivets you'll need a rivet hammer (pneumatic) and bucking bar. Here's a video on how to use a rivet hammer. Otherwise you'll need to find a shop that has one.

I happened to have everything from a previous project with Snap-on. The steel rivets require a higher PSI to squash. I had my gun setup at 120psi in order to get them to deform enough (1.5x the size of it's start diameter). Use several small c-clamps to hold the 2 pieces together while riveting so there's no play in the fitment. Sorry, I installed the new basket on a different day and forgot to take photos.